First I need to say that I won’t be using aluminum foils, but real capacitors.

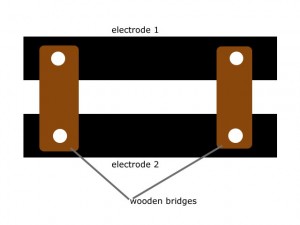

So let’s assume the electrodes are 2 ruler shaped metal pieces.

You can drill 4 holes, that would form an imaginary rectangle, two holes in each of the metal plates.

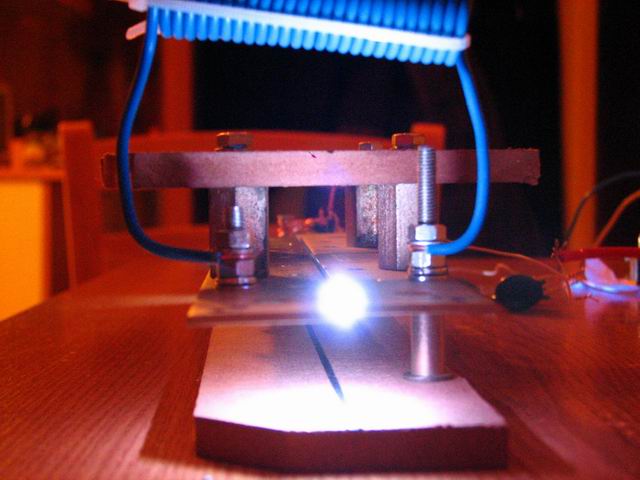

Using a non-conductive material, you can create two bridges between the two electrodes. This way you will have a rectangle shape, were the electrodes are parallel:

|

|

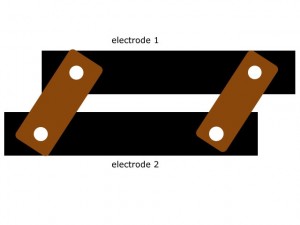

The good thing is that you can always loose the screws, so the rectangle shape can be easily shifted to the right, to a parallelogram shape.

This way the electrodes will always stay parallel, but the distance between then can be adjusted.

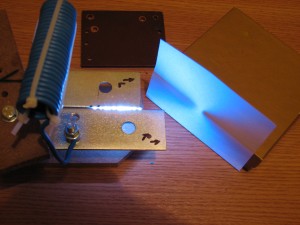

You will need to put some metallic spacers between the wooden bridges and the electrodes or else you’ll have arcs in that spot, that will burn the wood. It happened to me (see the marks left of the wooden bridges).

So one electrode can be free to shift left/right, and the other can be fixed to a holding plate.

Here’s my setup:

|

|

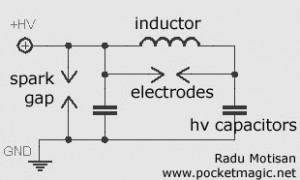

For the power supply I’ve used my ZVS driven flyback with built-in half wave rectifier, and a few hv ceramic capacitors (2x 18KV 3nF). Some designs use homemade plate shaped capacitors made of aluminum foil, but I don’t recommend it.

Here’s the laser firing, but apparently not working correctly:

The spark gap makes a lot of noise, and very bright discharges, so it’s very important to wear safety UV glasses.

A few videos:

For those of you willing to try this, you might need this as well:

Hope you enjoyed this,

Radu Motisan

I’m sorry, but this isn’t a laser.

As said in the article: “Here’s the laser firing, but apparently not working correctly”

Electrical discharge must be very fast. It should take no longer then few nanoseconds. Homemade caps with carefully chosen dielectric does the trick. Your suggestion about caps is missleading. I would love to explain more and be more polite but my english is not so good :).